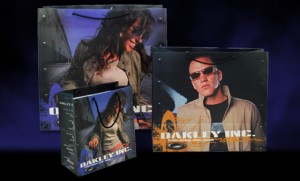

Businesses that use custom printing realize the importance packaging can have on their brand’s image. These businesses want their products to project their brand’s unique personality and they understand that custom packaging can do just that. Whether you are looking for printed restaurant bags, custom gift wrap or custom food packaging, at Morgan Chaney we make it our mission to educate and help you make the best selections for your distinct business needs.

Below our Design Studio offers you a few tips on how custom packaging works:

Printing in one color isn’t always a money saver

Printing in one color isn’t always a money saver

Many businesses believe that by custom printing in only one color, they’ll save a bundle. The reality is the second color choice is usually not that expensive. If printing in a second color will truly make your packaging stand out, don’t let a few cents per box or restaurant bag keep your business from making its mark. Where it can get a bit more costly is if you choose to add a third or fourth color. However, whether there’s a price increase or not, depends largely on the product you’ve chosen to print on. The best way to avoid sticker shock is by speaking with a member of our design studio, who can provide you with guidance every step of the way.

Limiting the art in your preferred design isn’t necessary

While there may be a slight savings potential in the cost of printing, it’s usually not enough to persuade companies from their first design. The reason being, ink isn’t really the expensive part of printing, the time it takes to set up is. One way to decrease custom packaging cost may be to actually increase your order size. Also, be sure if you are supplying your own design artwork to get exact specifications to avoid extra charges.

The difference between made-to-order and post printing

There are two options for ordering custom packaging, made-to-order and post. Made-to-order custom packaging is a process in which the base material is printed before its converted (formed, cut, glued, etc.) into the final product. This type of process allows for greater creativity as it can achieve 100% ink coverage and can utilize up to 8 colors on certain packaging products. This process is the most economical for large volume orders. Post printing, on the other hand is typically best for smaller orders with a quick turnaround, as it employs already manufactured products which are then imprinted on. There are limitations with post printing since the products have already been assembled, printing options are restricted to the front or back of the packaging.

Contact the custom packaging experts at Morgan Chaney, to help you create an entire program of matched custom packaging. Call 866-637-2270 so we can provide you with everything you need to achieve packaging that people notice.