Creating packaging for your brand can feel tricky. We broke it down for you.

With over 1 million retail businesses reaching new audiences through new channels, like Instagram and Facebook marketplaces, TikTok, and other social channels, brand loyalty sometimes feels like a thing of the past. Smart companies can use that to their advantage, though – for example, did you know that 64% of consumers buy something off the shelf without having been introduced to the brand first?

What spurs that impulse, you ask? Good packaging. According to a 2016 study on ecommerce opinions, premium-feeling custom packaging is one of the biggest deciding factors in purchasing habits of consumers.

That means that – so long as your product looks polished – you don’t need to be the biggest player in your industry to watch your stock fly off the shelves.

- Good custom packaging does these five things

- Different types of retail packaging to help define your brand

- Packaging materials: what to use and when

- Step-by-step: what you need to work with a packaging designer

- The production process: let's get technical

- Printing techniques: how logos and designs are printed

- Custom packaging FAQ: your questions, answered

- To sum it all up

- Free Resource: Fillable Custom Packaging Checklist (PDF)

- Subscribe

Good custom packaging does these five things

Any good, branded packaging exhibits five key factors:

- It tells a coherent story about your product

- It protects your product through shipping or display

- It gives consumers valuable information on whether your product is right for their needs

- It distinguishes your product from competitors’ offerings

- It invites consumers to think about the kind of person who would use your product

Branding should be aesthetic, yes, but it’s important to keep its form firmly rooted in function. As you’re creating custom packaging, remember to keep your key audiences in mind. What do they most need to know about your product? What sort of person would use your product, and what visuals might they be most attracted to? How far is your product traveling? What do your competitors’ brands look like, and how can you differentiate?

Retail packaging helps new customers understand your brand

Take the Korean cosmetics brand Stonebrick, for example. They opted for minimalist (but bright!) packaging with mix-and-match embossing and die cut shapes. (The designers at Established seem to have a bone to pick for anyone conflating “simple” with “boring.”) It’s bold, LEGO-like boxing that immediately tells you a story about the brand. The first thing you notice: the vibrant colors. The second thing: the only text on the front of the box, which is the brand name and product. In this case, you’ll also notice that every single product feels distinct but tied together by a brand ethos. It’s easy to pinpoint the target audience of this brand: eco-conscious, aesthetically-minded shoppers who care about the ingredients in products they consume.

Customers care about branding and unboxing. A lot.

According to Google, “the amount of time people have spent watching unboxing videos just on their phones is the equivalent of watching the holiday classic “Love Actually” more than 20 million times.”

And while we love Colin Firth, we’re way more invested in the fact that product unboxing is so popular that it’s a major category on YouTube. That’s right: people watch other people unbox products in their spare time. It speaks volumes about how important the look and feel of your packaging is.

Another stat you might need: 64% of consumers regularly buy a product because of how the packaging looks.

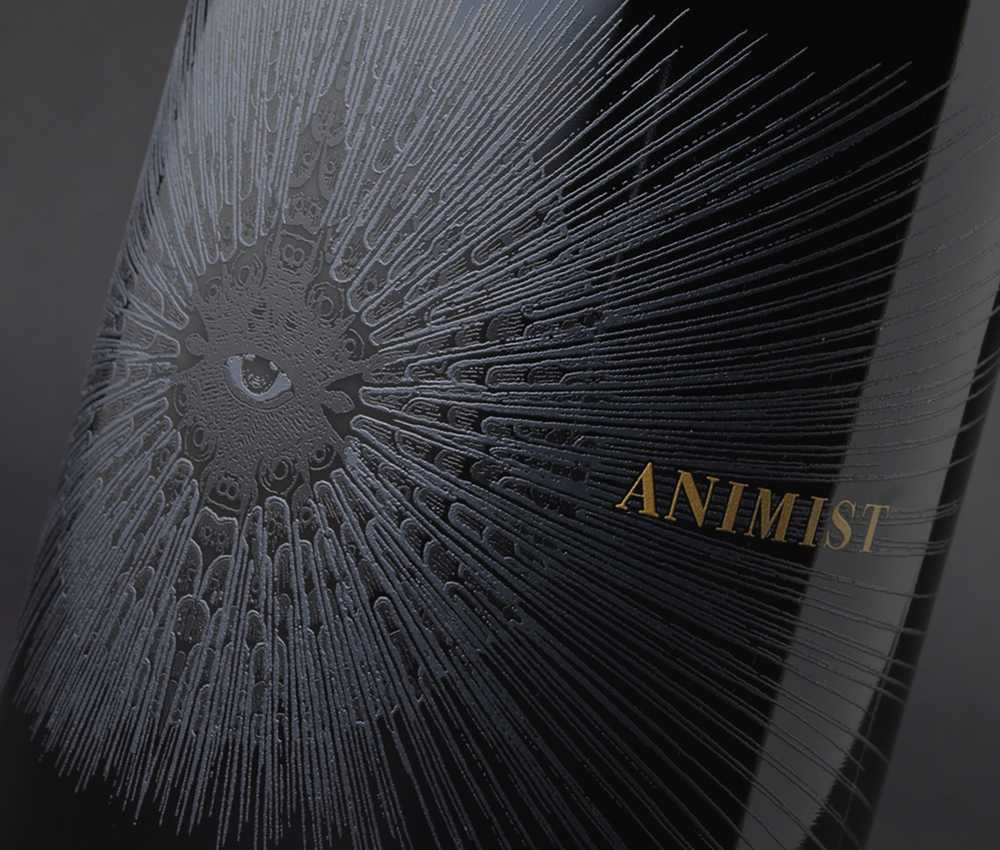

Think about it: when’s the last time you really bought a bottle of wine based on something other than how cool the label was? Good packaging makes a customer excited to get to the actual product. Most winemakers (like the ones below) understand that shelf appeal is one of the main drivers of consumer purchasing. The general consensus for customers seems to be that if you’re willing to invest time and money into designing your packaging, then you’ve probably done the same for your product. Good packaging inspires confidence in a product with or without brand recognition and before a consumer even opens the box.

Different types of retail packaging to help define your brand

Physical retail packaging

If you’ve got a brick-and-mortar store, there’s a couple of key types of packaging that could be great for your brand. Retail packaging doesn’t need to be mailed, so while it still should match your brand identity in terms of the materials it’s made from (in general, heavier paper weights feel more luxe, for example) it doesn’t have to stand up to any mail delivery service.

Custom folding carton boxes are a great option for shelf-stocked items. They can be as eye-catching as you’d like them to be, display important information about a product, and can even be lightly protective, depending on how your product is packed inside.

If you’re looking for high-end boxes, magnetic gift boxes and clear top boxes do an excellent job of protecting your products while displaying them in a premium way.

You may also consider purchasing custom bags (paper, plastic, or alternative) and custom tissue paper for your customers to take their purchases home with.

Ecommerce packaging

These days, it’s probably safe to say that most brands operate primarily online. Ecommerce retail packaging comes with its own set of needs, challenges, and customer payoffs. If your product is getting shipped somewhere, it needs to be able to stand up to the absolute packaging gauntlet that is the mail system. A checklist of items you might consider for your ecommerce brand, arranged for you from the outside of the packaging in:

- Branded mailing boxes or poly mailer envelopes

- Branded packing tape

- Branded shipping labels

- Branded tissue or other packing material

- Inserts to protect or organize your products

- Thank you note, return instructions, or other cardstock message

- Product box or bag

Packaging materials: what to use and when

When you’re working with a packaging designer, you’re likely to have a discussion about what kinds of materials you’d like to use to package your product. Bags and boxes can be made from a variety of materials – from traditional ones like paper and plastic to more obscure options like bagasse and bamboo. The amount of choices can feel a little dizzying to the uninitiated – so here’s a guide to the most common options.

Paper

When discussing paper products, you’ll want to know primarily about paper thickness (weight), the recycled content of the paper, whether the paper is recyclable or compostable, and what dyes and laminates are used in processing.

Paper thickness

Paper thickness, or paper weight, is measured in two common ways: pounds, and grams per square meter (GSM). You’ll see pounds used most often in the US, whereas suppliers from abroad use the metric system. The thicker the paper is, the higher the number in pounds or GSM will be. For reference, gift wrap tissue paper is often around 14 pounds. 80 pound paper is what’s found in traditional cardstock, and it’s also what we use in our premium EcoPlus shopping bags.

Recycled content

Recycled paper is placed into two categories: post-consumer and post-industrial. Some cities and states have ordinances that require paper bags to contain at least 40% post-consumer recycled content, so be sure to talk with your designer or order bags that meet these standards.

Recycling and composting

Paper bags are generally recyclable and compostable, making them an eco-friendly option for brands. However, certain things – like laminates, used in upscale shopping bags – can prevent bags from being broken down and repurposed. Make sure to talk with your designer about recyclable materials if it’s something you’re concerned about.

Plastic

Plastic packaging is not as common as it used to be, as both companies and consumers look for more sustainable options. But it’s still a very ubiquitous option for packaging.

When looking at options for plastic packaging, you’ll want to understand the differences between common plastics used, how plastic thickness is measured, and options for recycling plastic.

Types of plastic

Polyethylene (PE) is the most common plastic found in plastic bags. It comes in two different types – high density PE (HDPE) and low density PE (LDPE.) HDPE is often used for retail bags, and LDPE is more commonly used for things like grocery and garbage bags. You’ll also see polypropylene (PP) used – it’s a standard material for cosmetic bottles, pill boxes, and more. Other common materials include polyethylene terephthalate (say that ten times fast), polyvinyl chloride, and polystyrene.

How is plastic thickness measured?

Most people measure plastic thickness in mils (one thousandth of an inch.) For reference, a credit card is around 30 mils. Retail shopping bags are around 2 mils. Your designer will be able to help guide you through such specific choices, but in general, you want plastic over 1.5 mil for lightweight protection, and over 4 mil for particularly heavy duty protection.

Other packaging materials

Cornstarch, mushrooms, seaweed, sugarcane – as it turns out, most plant fiber can be used to make alternative packaging. When looking at alternative packaging materials, it’s important to note which materials are recyclable and compostable both by consumers and industrially. It’s surprising, but some alternative materials don’t always recycle well.

Step-by-step: what you need to work with a packaging designer

We’re going to assume that you don’t have an in-house designer (if you do, great! This part’s probably a good refresher) and that you might need some help gathering your materials to send to a packaging designer. Shameless plug: Morgan Chaney’s in-house designers can of course walk you through the process. But in case you’re just curious about how it all works, here’s what you’ll need.

Step 1: How big is your product?

Product dimensions will determine what size box will best fit your needs. You don’t want something too small, because obviously your product might not fit – but a box that’s too big will likely feel wrong or misleading to your customers, too. Have the height, width, and length of your product at the ready when discussing with a designer.

Step 2: What does a customer need to see on the outside of the packaging?

The answer to this question changes slightly depending on whether you’re talking about shipping boxes or product boxes. We’ll break them down below:

Shipping Boxes:

- Your logo (and you can get creative here – if pasting your logo on a box just feels too overdone, consider custom labels or packing tape)

- A mailing label with shipping address and your business’s name and address

- An indication of what the product is (unless you sell a particularly sensitive or personal item)

- Brand colors, patterns, or designs

- A quote or personal message to your customers

Retail Boxes:

- A product title

- Useful information about your product, like ingredients or ways to use it

- Your company’s logo and tagline

- A story about your product or brand

- Brand colors, patterns, or designs

Paper and plastic bags:

- Your company’s logo and tagline

- Brand colors, patterns, or designs

Step 3: It’s what’s on the inside that counts

Remember when you were growing up how some kinds of cereal had puzzles, pictures, and promo materials on the inside of the box? Some brands have recycled that idea in interesting ways, using the inside of their custom boxes and bags as real estate for secret messages, social media info, and other neat tricks.

Check out Thrive Market, for example, which uses the inside of their shipping box’s lid to provide a little custom extra to their customers:

You can print the inside of your packaging (both retail and ecommerce) with brand colors, patterns, messaging, and more. It’s a great way to differentiate your brand while staying eco-friendly by avoiding using additional paper or packaging materials.

Step 4: Find a good packaging designer

You don’t need to be a whiz in Photoshop, Illustrator, or any other design programs to put together a great looking package for your company. Bring those elements from the first few steps to a good designer and they’ll have a great starting point to really elevate your product.

A few things to look for in a designer:

- Communication

- How quickly does your designer communicate after you send a message to them? You want to make sure your designer is attentive to your product (within reason, of course – we all know that guy)

- Proof options

- What options are there for final proofing? Make sure you understand the process for suggesting edits, and make sure your designer sends you a copy of the design before final approval.

- Copy editing

- Some designers will help you edit your copy. It’s always good to have a second pair of eyes, even when you’ve double- or triple-checked the verbiage yourself.

- Graphical skill

- If your designer is doing anything more than assembling the elements you give them, make sure they’ve got a readily available portfolio for you to peek through. Additionally, sending them other packaging you like can help a designer settle in on exactly what you’re looking for.

Note: we offer free in-house design services to all of our customers! Work with our experienced packaging designers today >

The production process: let’s get technical

After you’ve settled on a designer, you’ll work together to create the final layouts for your packaging. This is a big step, and you’ll need to know a little bit about the standard production process before proceeding.

Preparing your artwork

When beginning the production process, you’ll either use a 3D box design service or lay your artwork out on a dieline with your packaging designer. Dieline templates allow for extremely precise control over layout, colors, fonts, placement of graphics and text, and alignment.

Following industry-standard guidelines for text and graphics helps ensure that your products print properly. Make sure that your proofs are properly set up with embedded graphic elements and proper cut and crop lines.

Use vectors wherever possible

Morgan Chaney recommends saving logos and other graphical designs as vectors (AI, SVG, and EPS files.) These files, unlike PNGs and JPEGs, can scale indefinitely – which means that no matter how big your package is, your images will appear crisp.

A word on fonts

Fonts that look good on the web don’t always translate well to a printed product. In general, thicker, bolder fonts print more legibly. Especially on dark backgrounds, make sure that you’re opting for bolder fonts. Your designer will be able to guide you on font size, but in general, avoid fonts smaller than 10pt on corrugated materials, and smaller than 6pt on paperboard.

Color codes: understanding the difference between CMYK, RGB, and PMS

If you’ve been on the internet, you’ve seen the RGB (often referred to as HEX) color model in use. On a computer monitor, red, green, and blue lights combine to create the images you see. CMYK refers to printing ink colors – cyan, magenta, yellow, and key (shorthand for black.) Because printed materials don’t have the intensity of light-based colors like a screen would, printing RGB colors results in a less vibrant end product. Using CMYK color settings when designing ensures that the colors appear appropriately when printed.

PMS stands for Pantone Matching System. It’s a proprietary color space used in a variety of industries (you’ll probably know it from those paint swatches and possibly the annual Color of the Year media blitz.) There’s a near-infinite amount of variation in CMYK colors – so Pantone set out to create a simpler, smaller, more standardized guide that can help brands figure out the shades and hues they want to use and simplify the printing process.

Dielines

Dielines are simply the unfolded representation of what your box or bag will look like before it’s assembled. It’s harder to print on pre-assembled 3D materials, and more expensive to ship them after, so a lot of custom packaging is printed on while it’s still flat.

In a dieline, green lines are bleed lines. Any art that needs to extend to the edge of a given part of the packaging (be it bag or box) should reach the green bleed line.

Red lines are fold lines. Logos and important art should be kept at least an eighth of an inch away from these lines to avoid issues when assembling.

Black lines are cut lines. Same thing here – at least an eighth of an inch away to avoid issues with artwork during production and assembly.

Note: We’ve got a wide variety of templates for common sizes of bags and boxes. Use them to mock up your packaging!

Printing techniques: how logos and designs are printed

Designers can use several different techniques to print on packaging. Options change based on your budget and how much product you need.

Offset printing

Offset lithography, or offset printing, is used for flat or folding packaging like cartons and large labels. In lithographic printing, images are attached to an aluminum plate and then transferred to a rubber mat for processing. The mat transfers the print to the material you’re using, and then (if selected), additional varnishes might be applied.

Flexo printing

Flexographic printing is used for high-volume labels and flexible (as opposed to rigid) packaging. In flexo printing, a rubber plate wrapped around a metal cylinder transfers logos and designs onto your packaging in sheets.

Digital printing

Digital printing is commonly used on corrugated and cardboard materials. You may have heard of inkjet printing – that’s a type of digital printing. Digital printing has become a common way of printing small-quantity orders, particularly for mailing boxes.

Other types of printing

Other types of printing like gravure and screen printing are used for very large and very small volumes of product, respectively. Both tend to have slower processing times due to difficult setup or operating techniques.

Custom packaging FAQ: your questions, answered

- What is custom packaging?

- How do I design a custom box?

- Why is custom packaging important?

- Where can I order custom packaging?

Custom packaging protects your products and provides visual interest to potential customers. Using your brand’s logo, company name, and visual design, custom packaging helps your product stand out on a crowded shelf (or in a crowded ecommerce environment!)

Think about what kind of packaging you need and what size will best display and protect your product. After, submit a request to our designers, and work with our team to finalize your product and submit an order.

Customers appreciate the extra mile some companies take to display their brands. Custom packaging can tell a story about the product inside in a visually-pleasing way, and can also inform or interest potential customers about what’s in the box.

Morgan Chaney offers a wide selection of custom packaging solutions, from bags and boxes to bakery supplies and custom tissue paper. We offer extremely affordable prices coupled with industry-leading customer service.

To sum it all up

Custom packaging boosts your brand recognition. Good custom packaging can inspire impulse buys by telling a story about your brand and informing potential customers about your product. Great custom packaging does it all while being eco-friendly and sustainable.

If it seems like there’s a lot of nuance to creating custom product packaging, it’s because there is. Luckily, we’re around to help. Our in-house designers can work with you to create the packaging your products deserve. And we’re around to help you every step of the way.

Check out some of the custom products we’ve helped customers create, and get started on your own project today.

Free Resource: Fillable Custom Packaging Checklist (PDF)

Sign up below to get our free fillable custom packaging checklist. It’s a great step-by-step guide for everything from brainstorming packaging designs to working with designers.