COVID-19 has impacted all of our lives. Some of the effects have been more drastic and widespread than others.

The packaging industry, like many others, has been facing several serious issues regarding supply chains, labor shortages, and shipping issues. These setbacks have greatly impacted our ability to do business as usual. At Morgan Chaney we deeply care about our customers’ success and these issues are not how we wanted to end the year 2021.

As of writing this, our sources for packaging products have changed dramatically over the course of the year. Raw materials cost more than they used to, minimum quantities for custom orders have increased, and shipping costs have skyrocketed. We are doing our very best to stay ahead of these complications and notify our customers of what their options are in the short term.

Here are some of the reasons for these dramatic packaging supply chain issues, explained in detail:

Shipping Delays and Freight Costs

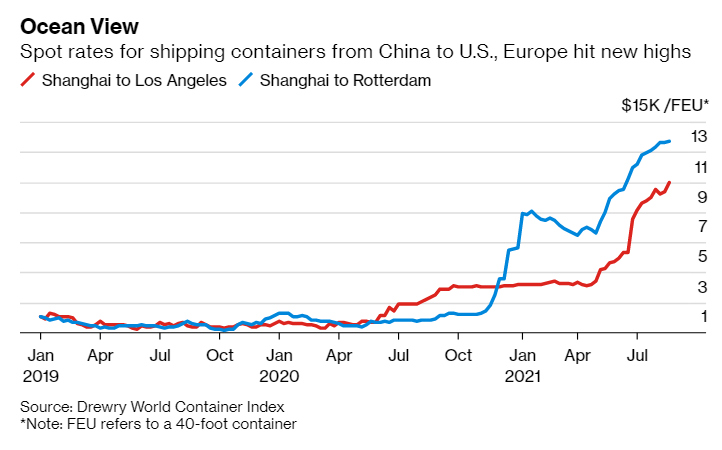

Freight costs for packaging shipped from overseas has risen dramatically in price this year. After shutdowns and production slowdowns seemingly ended, the after effects hit full force. The price for a shipping container across the pacific is now more than 6 times higher than in May 2020.

Port congestion has also been a huge issue in the supply chain. Ships are getting stuck at port with nowhere to dock and unload, and goods may be sitting on a ship for days or weeks before finally being unloaded. In the packaging industry, lead times for packaging shipped from China has doubled or tripled due to these issues.

“Port congestion and a shortage of container shipping capacity may last into the fourth quarter or even mid-2022,” said Hsieh Huey-chuan, president of Taiwan-based Evergreen Marine Corp. Right now, it’s expected that these issues will last well into 2022, so it’s important to plan way ahead for any of your essential needs.

The cost of shipping within the U.S. has risen as well. FedEx recently announced new peak surcharges heading into the busy holiday season. USPS has announced a proposal for temporarily higher shipping rates for the holiday season as well. Everyone should expect shipping delays and out-of-stock issues this holiday season as supply tries to catch up with the demand of a post-covid economy where people are spending money again. You can also expect all major shipping carriers to pose higher than normal price increases heading into 2022.

Supply Chain Issues

Supply chain issues. We’ve all heard it at this point. The imbalance between supply and demand is causing material prices to rise faster than average. These price increases have to be absorbed along the supply chain, and inevitably are passed on to consumers.

It’s not just about increased prices though. The supply and demand for raw materials and crucial parts is backlogged, and manufacturers are stuck waiting a long time for their materials. Every product that requires manufacturing or assembly is at the mercy of their suppliers.

For example, there is a shortage of paper that impacts many industries. You probably noticed the toilet paper shortage early on, but other products made from paper are also backlogged due to a lack of paper materials being produced. Some popular paper-based packaging items are expected to be out of stock until mid-2022!

Chris Williamson, chief business economist of IHS Markit says, “This reflects surging demand for parts at a time when supply is being constrained as the Delta variant disrupts production in many countries, notably in Asia, and shipping remains fraught with logistical issues stemming from the pandemic.”

Labor Shortages

Labor shortages have a variety of causes, many related directly to the COVID-19 pandemic. Some jobs are offering higher wages and bonuses to attract people to apply for open positions. The Delta variant of COVID-19 continues to cause issues with the labor force as entire teams of workers may be quarantined for 14 days from a single exposure. Different countries are handling the quarantine process differently, so there are varied results across the globe.

The pandemic also sparked a lot of early retirement and career changes, leading to shakeups in the labor pool for any given industry. The desire to work from home long term has changed many people’s job priorities and career aspirations. There has also been an issue of childcare during school closures and now as many children are being exposed to covid at school and needing to quarantine at home.

In the U.S. a record 4.3 million workers quit their jobs in August 2021. It’s clear that the job market is in a state of transition. In the mean time, employers are doing the best they can with limited staff and resources.

What We Can Do

The combination of all of these issues is causing frequent inventory issues, extremely long lead times for custom printed packaging, and delays in shipping and receiving orders.

The experienced packaging consultants at Morgan Chaney are always here to help you get packaging. It may be too late to order custom packaging for the holiday season, but we also offer in-stock packaging options that may serve as an interim solution for your business’s needs.

If you want to start planning your packaging needs for next year (which we highly suggest you do!) contact us to get started today. Planning WAY ahead is the way to go, at least for the next year or so. Nobody really knows what will happen next, but we are hoping to get back to some stability within the next year.